The Truth Behind 1000 Thread Count Sheets

Share

We all assume that a higher thread count means better quality but thread count is no guarantee of quality. When starting in 2010, we were in for a big surprise.

Green as they come

In January 2010, we were excited to be starting a new business. We wanted to sell high-quality cotton sheets, so asked Portuguese producers for 1000 thread count sheets - 2000TC if they made them.

Honestly, you could hear a pin drop.

After an awkward silence, the experts laughed (politely) and explained that if we wanted to sell high-quality, we didn't want 1000 thread count sheets because they were considered an industry joke. In fact, a US retailer was sued over high thread count sheets in 2005, but we'll get to that later.

How can this be?

Super high thread counts are commonly achieved by using a combination of double or triple insertions, and/or by counting the invisible threads in a multi-ply yarn. Invisible threads?

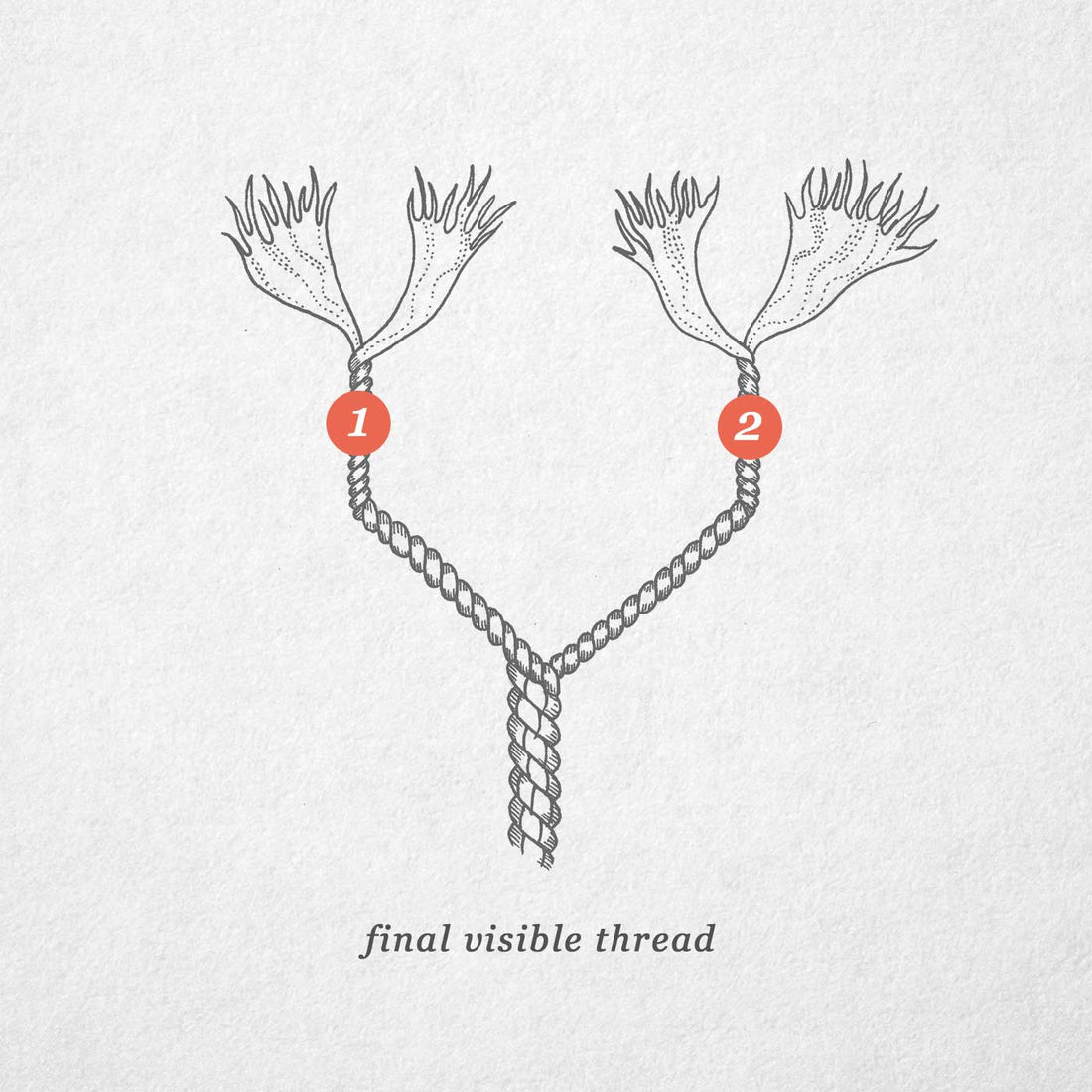

Multi-ply yarns are made by twisting two or more threads together. The simplest form of multi-ply yarn is called a two-ply yarn (illustrated).

In a two-ply yarn, each visible thread you see is made up of two invisible threads twisted together (a bit like rope). In a three-ply yarn, there are three invisible threads, and so on.

So if we weave a 333 thread count sheet from a three-ply yarn, we can advertise a thread count of 1000 (333 x 3). In reality, high thread count sheets don't use tidy mathematics like this, but the example illustrates how multi-ply yarns increase thread count.

High thread count sheets can mislead consumers

In the commercial world, we're given all the information we need to understand what we're buying; things like cotton grade, cotton origin, yarn-type, weave-type and more.

However, in the retail world, these critical quality indicators are hard to find. And because we as consumers have been taught to equate thread count with quality, we naturally assume that in order to make 1000 thread count sheets, the finest quality cotton is required - but it's not.

And that's at the heart of a modern sheet recipe (discussed here) which has resulted in a class action law suit, and prompted the US Federal Trade Commission to warn the textile industry about thread count claims it considers misleading

“…we believe that consumers could be deceived or misled by the practice of stating an inflated thread count, achieved by multiplying the actual count by the number of piles within the yarn."

— US Federal Trade Commission

A controversial sheet recipe

The problem with high thread count sheets is that they take advantage of an assumption that quality cotton and manufacturing is required to make them. But a higher thread count doesn't fix poor cotton or manufacturing, that's one reason why Bed Bath & Beyond in America were sued. And this is the problem with judging sheets using thread count; thread count doesn't have that much to do with quality. You can make 'bad' high thread count sheets, in fact, you can make utterly terrible high thread count sheets. And you can also make fantastic low thread count sheets.

At this point, it's important to stress that not all 1000TC sheets are subject to criticism; it comes down to the quality. But when 1000 thread count sheets are made from the finest quality cotton (like many assume) they actually cost NZD 1300+ a set. And even when made from really great cotton, they still cost NZD 700+ a set. Really?

Basically, more threads require more cotton, and more cotton equals a much higher price. So when rare, sought-after and expensive cotton is used in a sheet recipe which consumes double or triple the cotton, you get an eye-watering price.

Hotels prioritise quality over thread count

Interestingly, hotels prioritise quality over thread count and also need a reasonable price. That's why hotels generally use low thread count sheets (250TC). Fewer threads require less cotton, less cotton means lower costs, and this allows hotels to get quality for a reasonable price. See here to learn more about the differences between hotel and retail sheets.

So what about high thread count sheets that don't cost NZD 700+? In order to make high thread count sheets affordable, quality is usually compromised somewhere. By lowering the quality of the cotton, or the manufacturing, worker conditions, chemical recycling, chemical disposal etc, high thread count sheets can be made more affordable.

Does it matter? That all depends on the individual, and we can't stress this enough; if you're happy with your sheets, that's all that matters. But if 1000 TC sheets you've purchased haven't lived up to the hype, this article attempts to explain why.

The higher the thread count, the hotter the sheet

Over the years, countless people have told us they're too hot at night. And when asked what thread count they buy, people proudly state nothing under 600TC. If you're hot at night, then high thread count sheets are some of the worst sheets you could buy because besides synthetics, 1000TC sheets are the hottest, non-flannel sheets available.

High thread count sheets are hot for two reasons; 1) the amount of cotton in the sheet making them thick. 2) the sateen weave which while soft/silky, doesn't breathe and traps heat.

If you're always cold at night, high thread count sateen sheets are a great choice. But if you're hot at night, or sleep with a foot hanging out of bed, go for low thread count percale sheets like our classic hotel sheet. Less cotton makes them finer and the percale weave breathes.

A New Zealand 1000 thread count sheet

Left sheet: A brand new, 1000 thread count (TC) sheet, cold washed, and air dried on an indoor clothes rack. It was purchased from a chain of designer bed linen stores in New Zealand, retailing for around $320 per Queen set.

Right sheet: A 435 thread count (TC) sheet from The Hotel Sheet after fives years of use in rotation with three other sheets (slept in, washed then dried every third week for five years).

In terms of straight out quality, this is an unfair comparison because the sheet on the right is much higher quality (so costs more). But in this instance it's relevant because we're simply using it to show what the sateen weave should look like.

To begin with, we're looking at the underside of a sateen weave, so although the ridges we can see won't directly touch your skin from the bottom sheet, they will from the top sheet.

OK, so what exactly are these ridges?

Well, they're not particularly soft and while they improved after ironing, they didn't get much better in many areas (and we have one of those steam irons).

To be honest, we had no clue what was going on, so enlisted help from a lovely textile expert who knows her stuff, and who happened to be visiting (handy that).

She said that when sheets (or any fabrics) are washed the first few times, stresses within the yarns/threads, which occur during manufacture, are relaxed. Initial stress relaxation is normal, but should be even and of minimal amount. Otherwise there is noticeable shrinkage in size and change in fabric appearance.

She suspects uneven stress on the warps and wefts (vertical and horizontal threads), and possibly inconsistent thread twist (or windings), may have caused the fabric to appear puckered and uneven after it was washed.

OK, so these ridges are probably the result of lower quality manufacturing . And in the same way that a high thread count doesn't guarantee quality cotton, it also doesn't guarantee quality manufacturing.

Whatever the cause, 'exclusive' and 'designer' sheets shouldn't really do this.

Why doesn't the 1000TC sheet look finer?

Some of you may have also noticed that the 1000TC sheet doesn't look finer than the 435TC sheet, if anything, it looks bulkier.

This is another reason why high thread count sheets can mislead consumers. We tend to think that a higher thread count translates into finer quality.

But depending on the cotton, multi-ply threads end up thicker because all those invisible threads which were twisted together make threads bulkier. To see this visualised, compare the multi-ply thread (1) with the single-ply thread (2) in the illustration.

So where does this leave us?

We're going to tell you to spend more – right?

Well, cotton products in general have a horrifying churn rate (mainly due to cheap fashion) and the textile school at the University of Otago estimates that kiwis toss 37kg of home textiles per person, per year.

So there are strong arguments for spending more but less often (as opposed to spending less, more often). One being the amount of drinking water cotton crops consume. Cotton is universally acknowledged as a thirsty crop so the more often we buy, the more of the world's drinking water we consume - something we don't appreciate in a rainy nation like New Zealand.

We all know that buying quality reduces waste but it's an issue of cashflow for most of us, and regular sales are also better for retailers. So this has been our challenge, could we produce a cost-effective sheet that performs better than the 1000 thread count sheets we've tested?

Enter The Classic Hotel Sheet. This is a 100% cotton sheet used in high-end hotels throughout Portugal and Europe. Remember slipping between the sheets in an amazing hotel and feeling those cool and crisp sheets? Then this is the sheet for you, great for hot sleepers, summer or for people who prefer crisp feeling sheets.

And for those looking for the best-of-the-best, we have The Egyptian Hotel Sheet. A similar cool and crisp recipe but made from the very best cotton; 100% DNA tested long-staple Egyptian cotton.

As an alternative to buying from us, the best place to buy bed sheets is from any company that understands cotton is more important than thread count. Look for companies that state a cotton grade such as medium-staple or long-staple cotton.

There's a difference between Percale and Sateen, especially if you prefer warmer sheets over cool and crisp sheets. So stay in touch for information on how sheets are made and how different techniques effect the way sheets feel and last.

Future posts will also discuss the different types of cotton quality, threads per square inch vs threads per square 10cm and much more.

Thanks for reading. For more insight into how bed linen is made, tips and special deals, subscribe to our newsletter below.

What we sleep on at home

Christina is menopausal, and like most men, I've always slept hot. The only reason we sell the sheets we sell, is because after 15 years sleep testing sheets in a temperature controlled bedroom, these sheets did the best job of regulating temperature.

But they're not a miracle cure, sleep is complex. You can't sleep in PJs or other bed clothes and expect temperature regulating sheets like ours to work. Likewise with puffy duvets or any kind of human-made fibre like poly/cotton or rayon - or even rayon blends sold as bamboo/cotton. Avoid! And if they work for you, great. But that just means you don't struggle with temperature as much as we do.

Natural fibres like cotton or linen, woven for airflow work best but we even found linen hotter than our sheets - thickness for any reason is always hotter. This also means you have to be able to see through the sheet. The trick? Find finer sheets made from decent cotton, yarn and weaving so you still get decent wear. Hence The Hotel Sheet.

Shop temperature regulating sheets

What do others think?

Click the small speech bubble under the Facebook post to see comments from other New Zealanders - an interesting read. And hey, why not join in?

More reading and reference:

- US Federal Trade Commission: Letter to the National Textile Association

- The New Yorker: Bed, bath & beyond class action suit

- ABC News: The truth behind thread count

- Wikipedia: Plying

- Wikipedia: Units of textile measure

- Wikipedia: Warps

- Wikipedia: Wefts (Warp and woof)

- Wikipedia: Thread twist per inch

- The Hotel Sheet: Sheet shopping; how can you tell what you’re buying?

- The Hotel Sheet: The truth about Egyptian cotton